At the International Conference Future Open-Cast Mining in Freiberg, Germany (15–19 September 2025), GoldenRAM showed how High-Performance Computing (HPC) through the CLOUDUT project[1] combined with FLAC3D simulations is reshaping geotechnical risk monitoring in open-pit mining. The case study focused on the Roșia Poieni copper mine in Romania, where large-scale modelling is helping to better understand slope behaviour and prevent costly failures.

[1] CLOUDUT is managed by GoldenRAM partners UTCN (Project title: Cloud Cercetare UTCN – CLOUDUT MySMIS ID: 124493, Contract no.: 235/ 21.04.2020)

Dorel Gusat (UTCN) showcasing how FLAC3D supports the monitoring of slope stability and stress changes in open-pit mining at Future Open-Cast Mining in Freiberg

Why slope stability matters

In open-pit mining, every bench excavated changes the way stress is distributed in the surrounding rock. This continuous reshaping of the underground environment inevitably increases the risk of slope instability. Even relatively minor shifts can put equipment and personnel at risk while also forcing operations to halt—sometimes for weeks or months.

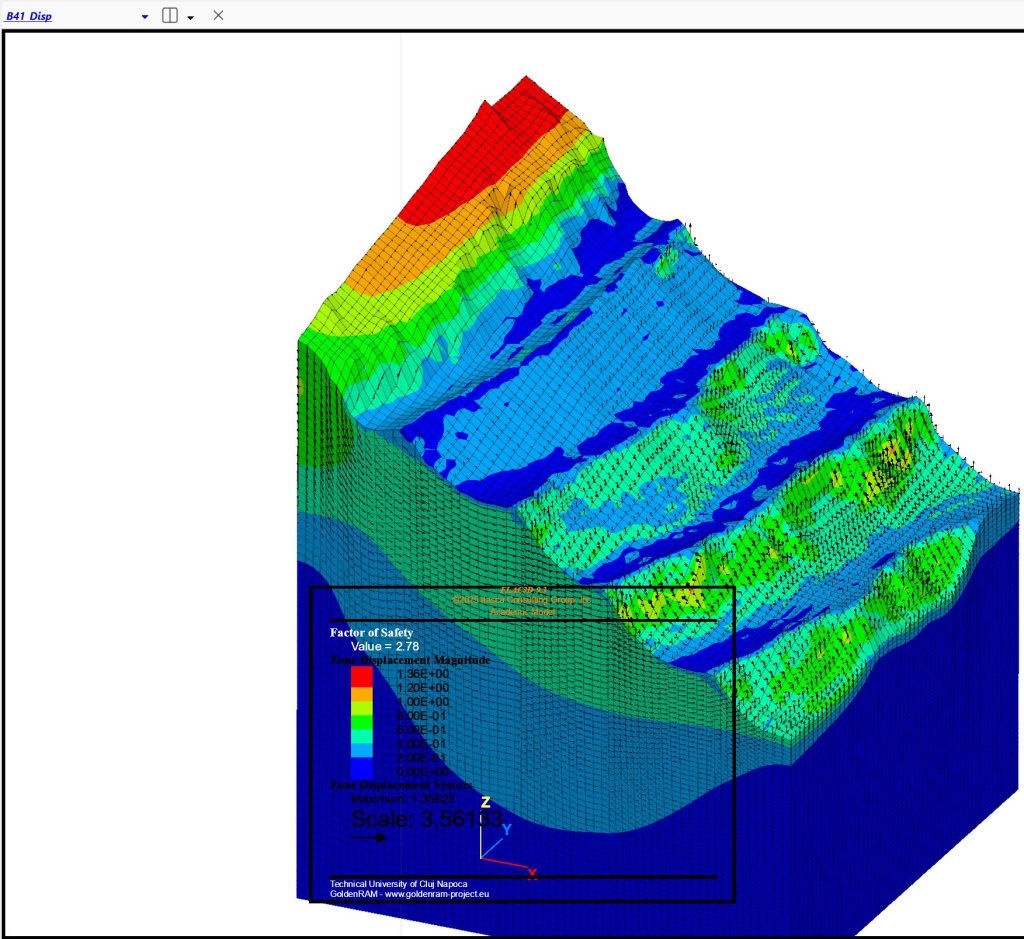

Through advanced numerical modelling in FLAC3D, the GoldenRAM team can simulate how stresses redistribute during excavation, anticipate failure mechanisms such as sliding or toppling, and track progressive deformations that may evolve into landslides. These predictive insights allow engineers to adapt strategies proactively rather than respond after an incident occurs.

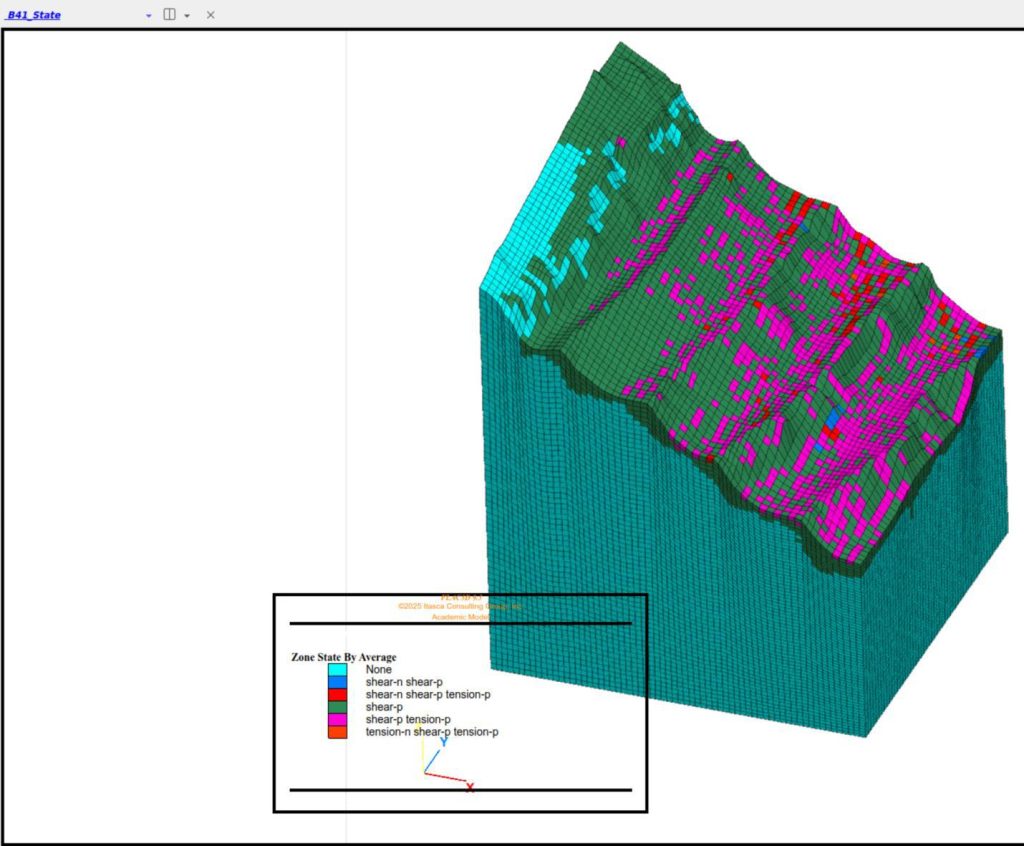

How FLAC3D visualises slope instabilities: example of zone state for B41

How FLAC3D visualises slope instabilities: example of displacement magnitude

Supercomputers at work

Behind these simulations lies a powerful computing infrastructure. The University of Cluj-Napoca (UTCN) provides a High-Performance Computing Centre that supports large-scale geotechnical modelling. The system consists of multiple computing nodes with hundreds of cores and terabytes of memory, supplemented by GPU accelerators capable of handling vast 3D models. With ultra-fast internal and external connections, researchers can process and analyse enormous datasets efficiently.

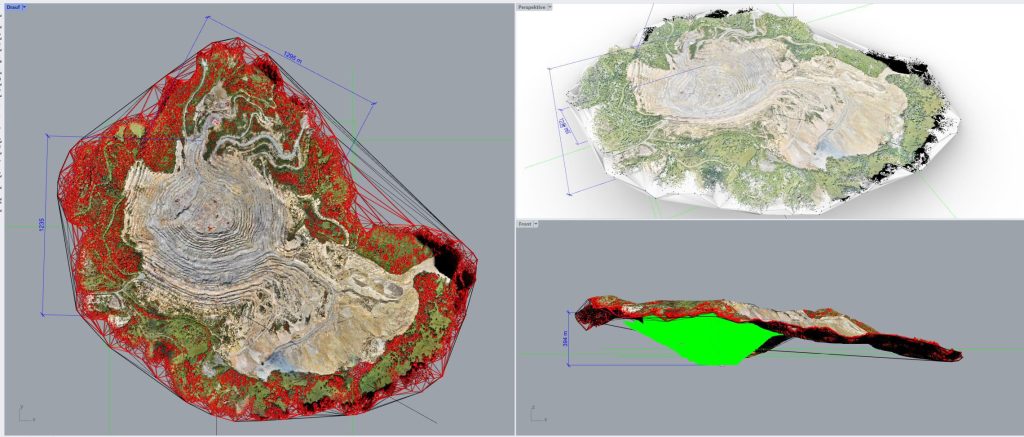

One striking example is the creation of a triangulated surface model of the Roșia Poieni pit containing 1.4 billion points. From this, a cross-section with over 3,000 points was generated and exported into FLAC3D, allowing the team to reconstruct the true geometry of mine benches before drone flights were conducted.

Triangulated surface of the Open Pit visually showing the scale of data involved

From simulations to actionable tools

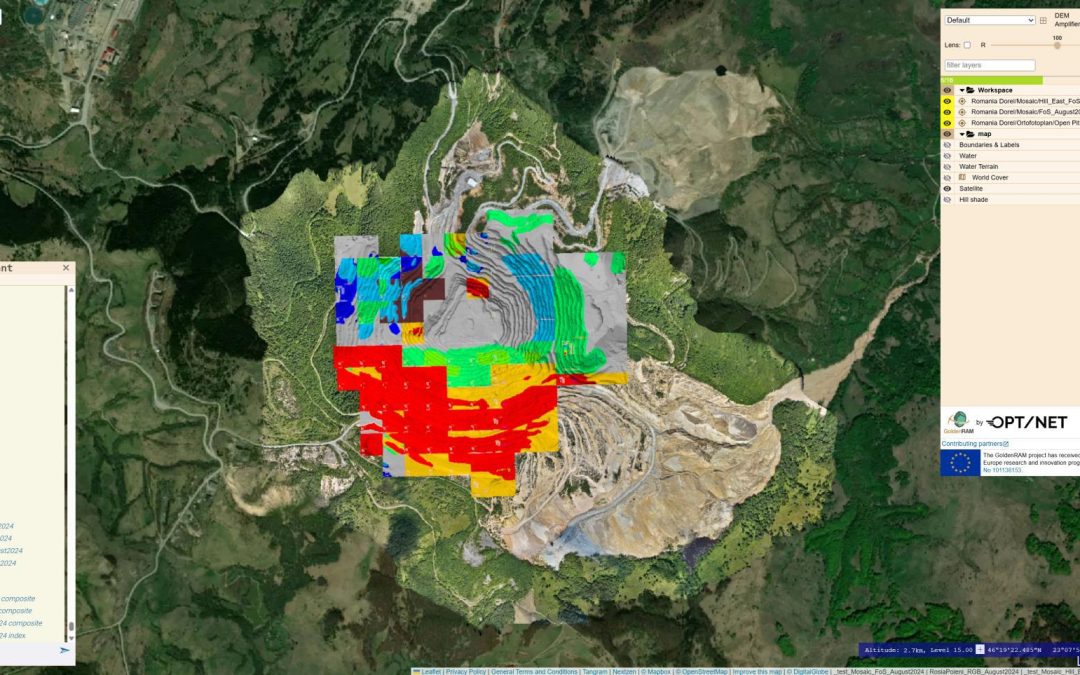

What makes GoldenRAM’s work particularly valuable is how these simulation results are shared. Through the GoldenRAM Platform, developed by OPT/NET, engineers and mine operators can interact directly with the findings. The platform displays block state maps showing where shear or tensile stresses are active, overlays displacements across zones, and provides RGB-based 3D inspections enriched with critical slope stability information.

This near real-time awareness ensures excavation strategies and blasting schedules can be adjusted before risks escalate. It also allows validation of reinforcement designs and supports back-analysis when new monitoring data, such as prism or radar measurements, becomes available.

A step forward for sustainable mining

GoldenRAM’s integration of geotechnical science, HPC, and remote sensing highlights a forward-looking path for Europe’s mining industry. By anticipating risks, mining operations can not only safeguard workers and equipment but also reduce costly disruptions and strengthen long-term sustainability.